+919871690592

9am to 6 pm (+5:30 Hrs GMT)

+91(124)4788700

marketing@a2zfiltration.com

+919871690592

9am to 6 pm (+5:30 Hrs GMT)

+91(124)4788700

marketing@a2zfiltration.com

Exhibition

Booth No. 3018, 3020

29 April

01 May, 2025

Miami Beach Convention Center, Miami, Florida USA

Exhibition

Hall No. 8, Stand A9

30 June

02 July, 2026

Cologne - Germany

Booth No. 533

Oct

10-12, 2023

Chicago, Illinois

- USA

FILTXPO 2022

Booth 1221

MAR 29-31, 2022

Miami Beach Florida

- USA

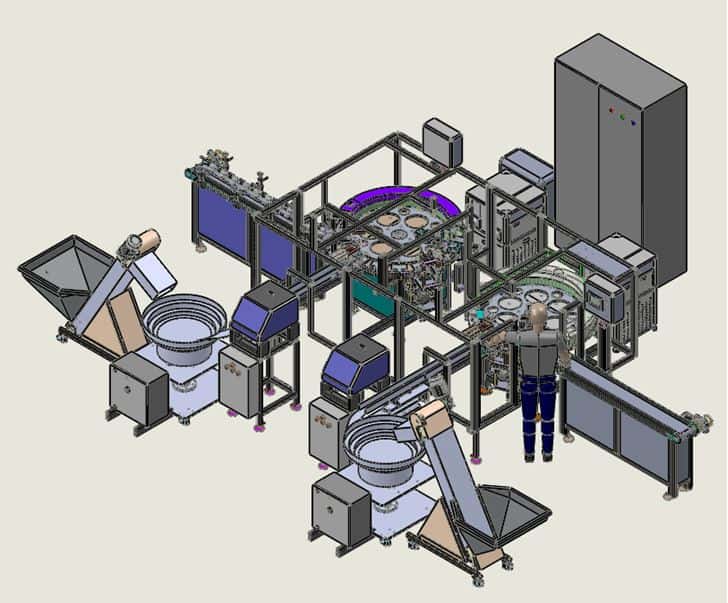

Built to purpose automation

An Example of this is Filter Assembly Cell as shown in attached 3-Dimensional Sketch, which shows an A2Z built to purpose automatic assembly cell, used to manufacture medical filters ( refer to picture named 3D view of assembly cell). The customer came to A2Z with a mandate to produce the filter with minimum human contact as well as throughout of 40 filters per minute. The product was required to be processed in a controlled environment due to the fact that the product was used in medical application and the media could not be exposed to any contaminants.

A2Z Filtration’s team worked with the customer to develop an acceptable concept. After approval of the same A2Z produced preliminary 3-Dimensional designs in SOLID WORKS. After detailed discussions, involving a study of the customer processes, input specification, capacity, changeover requirements and needs of automation, the customer gave the approval. The A2Z Filtration’s design team worked closely with the customer and other stakeholders to build a complete production line.

From the start of the project to installation at the customer’s facilities and validation trails, the project took six months to complete. During this time, there were certain design changes as well as the addition of processes to meet the sensitive nature of the product. A2Z engineered an acceptable solution and provided Fit to purpose fully automated production lines.

These lines offer excellent value based on the filter manufacturers exact needs and budgets.

Booth No. 3018, 3020

Miami Beach Convention Center, Miami, Florida USA

Copyrights © 2019 A2Z Filtration Specialities Pvt. Ltd. All rights reserved.